✔ Patented Chemical-Resistant Tape for PPE Enhancement

- Specifically designed to reinforce personal protective equipment (PPE) by sealing gaps at interfaces, such as gloves, sleeves, boots, zippers, and respirator edges.

- Helps maintain a near-airtight environment while allowing full mobility.

- Effectively protects against chemical splashes, aerosolized threats, and particulates.

✔ Industry-Leading Chemical Protection

- Tested per MIL-STD-282: Provides a minimum holdout time of 8 hours against deadly chemical warfare agents, including Nerve (VX), Sarin (GB), and Mustard (HD).

- Tested per ASTM F739: Demonstrates chemical resistance for at least 160 minutes against 15 hazardous chemicals from the ASTM F1001 list.

- Compatible with Level A, B, and C protective suits as well as NFPA-rated garments.

✔ High-Performance Material and Adhesion

- Features a polyisoprene-based (rubber) adhesive for superior chemical resistance and strong bonding.

- Ensures secure sealing yet can be removed without damaging reusable protective garments.

- Designed to reduce gross liquid flow at interfaces, enhancing protection against splashes and aerosols.

✔ Versatile and Multi-Purpose Application

- Can be applied for emergency containment, shelter-in-place scenarios, tent or pipe sealing, and hazardous material response (HazMat).

- Ideal for hazardous waste cleanup, decontamination zones, industrial chemical exposure, and emergency preparedness.

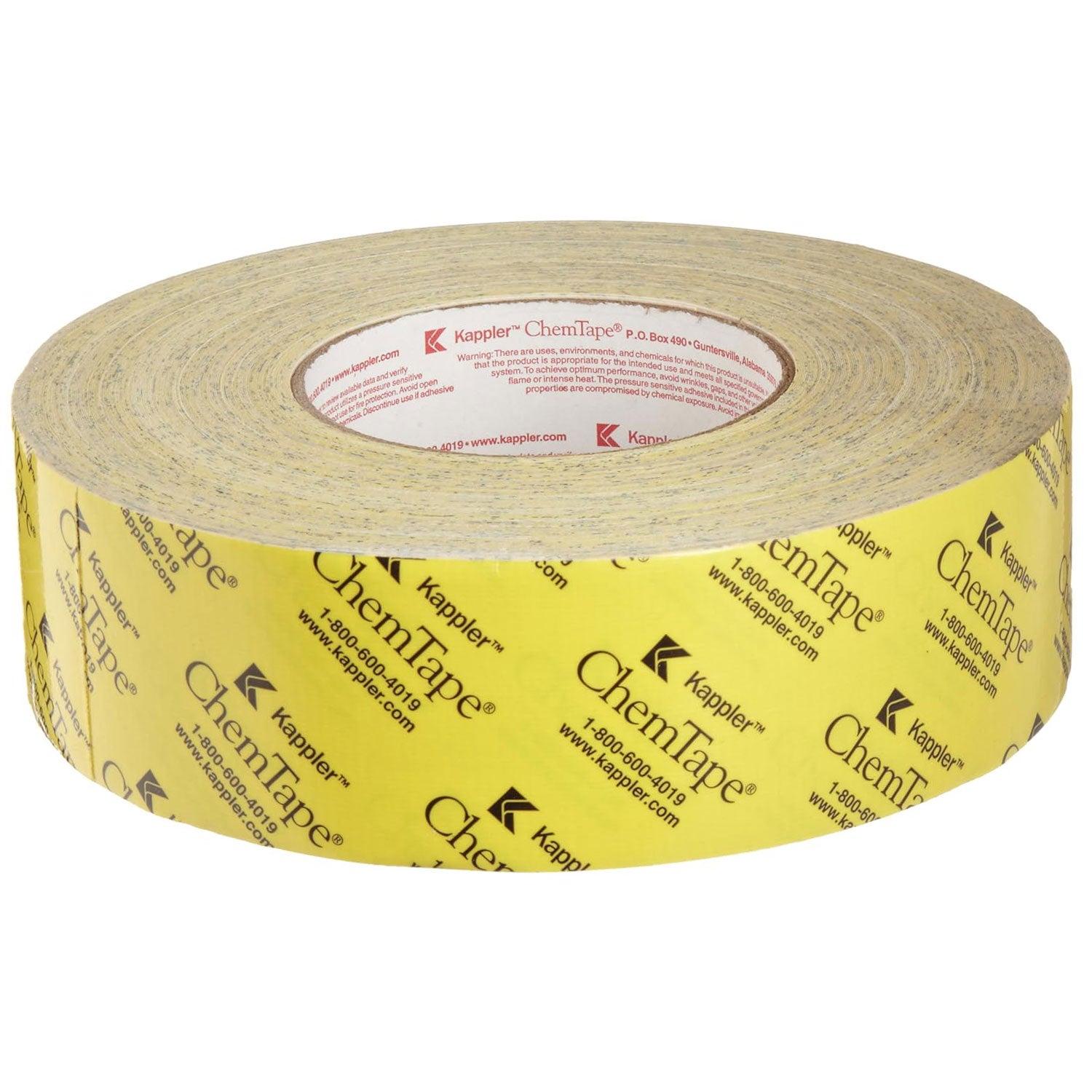

- High-visibility yellow color allows for easy identification in critical situations.

✔ Practical, Durable, and Easy to Use

- Pressure-sensitive adhesive ensures secure adhesion with minimal exposure to airborne threats.

- Wide coverage: Each roll measures 2 inches wide and 60 yards long, providing ample material for extended use.

- Long-lasting shelf life: When stored correctly, ChemTape® has no known degradation over time.

✔ Manufactured in the USA

Designed and manufactured under strict quality control standards in the United States.

Adhesive: Polyisoprene-based (rubber) adhesive for strong, long-lasting adhesion while maintaining chemical resistance

Backing Material: High-visibility yellow film for easy identification in hazardous environments.

Weight and Dimensions:

- Approximate weight per roll: 1.5 lbs (0.68 kg)

Dimensions:

- Width: 2 inches (5.08 cm)

- Length: 60 yards (54.86 meters)

- Thickness: Designed for flexibility while maintaining durability.

Protection Level:

Kappler ChemTape® is a critical addition to PPE gear, designed to enhance protection at vulnerable suit interfaces by sealing gaps and reinforcing coverage against hazardous substances.

Splash-Resistant Defense – Shields against hazardous liquids, aerosols, and particulates, reducing exposure risks at PPE junctions.

Chemical Warfare Agent Resistance – Tested per MIL-STD-282, providing at least 8 hours of resistance against deadly agents, including VX (nerve agent), Sarin (GB), and Mustard gas (HD).

Industrial Chemical Protection – Certified under ASTM F739, ensuring at least 160 minutes of holdout against all 15 highly toxic chemicals listed in ASTM F1001.

PPE Compatibility – Seamlessly integrates with Level A, B, and C protective suits, as well as NFPA-rated garments, ensuring optimal performance in hazardous environments.

Certifications & Compliance:

Kappler ChemTape® meets stringent industry standards to ensure superior protection in hazardous environments:

- MIL-STD-282 – Rigorously tested for resistance against chemical warfare agents, including VX (nerve agent), Sarin (GB), and Mustard gas (HD), with a minimum holdout time of 8 hours.

- ASTM F739 – Certified for chemical permeation resistance, demonstrating a holdout time of at least 160 minutes against the full ASTM F1001 list of 15 hazardous chemicals.

- NFPA Suit Compatibility – Designed for use with NFPA-rated protective garments, ensuring seamless integration with high-performance hazmat suits.

Manufactured in the USA – Produced under strict quality control guidelines, ensuring reliability, consistency, and adherence to industry-leading safety standards.

Kappler ChemTape® is an essential tool for professionals operating in high-risk environments, including:

Hazmat Teams & First Responders – Critical for decontamination, hazardous material spills, and emergency response.

Military & Defense Personnel – Enhances protective gear for CBRN (Chemical, Biological, Radiological, and Nuclear) operations.

Industrial & Chemical Workers – Provides an additional safeguard for those handling toxic substances, solvents, and hazardous waste.

Laboratory & Research Staff – Protects against accidental chemical exposure in high-risk lab settings.

Disaster Response & Biohazard Cleanup Crews – Ensures secure sealing of PPE in areas affected by contamination or infectious materials.

Kappler stands behind the quality and performance of ChemTape®, ensuring that each roll meets stringent manufacturing and testing standards. While ChemTape® is a single-use product, Kappler guarantees that it will be free from material defects and workmanship flaws at the time of purchase.

- Coverage: The warranty covers defects in materials and manufacturing that could affect performance.

- Exclusions: The warranty does not cover damage due to improper storage, misuse, or application errors.

- Claims Process: If a defect is discovered, customers should contact their distributor or Kappler directly for assistance.

To maintain ChemTape’s® optimal performance, proper storage is crucial.

Ideal Storage Conditions:

- Temperature: Store at 73°F (23°C) for best long-term preservation.

- Humidity: Keep in a dry environment to prevent moisture buildup.

- Light Exposure: Avoid direct sunlight or prolonged UV exposure, which could affect adhesion.

- Maximum Storage Temperature: ChemTape® can be stored at temperatures up to 120°F (49°C), but extended exposure to high heat may accelerate adhesive degradation.

- Storage Best Practices:

- Store in original packaging until use.

- Keep away from chemicals, solvents, or corrosive substances that could affect adhesive integrity.

- Do not store in areas with high humidity or fluctuating temperatures, such as near HVAC vents or industrial equipment.

- Avoid stacking heavy objects on ChemTape® rolls to prevent deformation.

By following these storage guidelines, ChemTape® will remain ready for use whenever needed, providing reliable chemical resistance and PPE reinforcement in critical environments.

Shelf Life:

ChemTape® offers a virtually unlimited shelf life when stored under proper conditions. Unlike many PPE adhesives that degrade over time, ChemTape® maintains its effectiveness thanks to its polyisoprene-based adhesive and durable backing material.

Key Shelf Life Features:

- No expiration date when stored correctly

- Adhesion and chemical resistance remain intact over time

- No known degradation of protective properties in ideal conditions